Understanding the Importance of Bursting Strength Tester in Quality Control Processes

In the realm of quality control processes, the significance of a bursting strength tester cannot be overstated. As industries continue to prioritize product durability and performance, the reliability of materials under pressure is crucial. According to a recent report by Technavio, the global market for bursting strength testers is expected to grow at a CAGR of 5.12% from 2021 to 2025, highlighting the increasing demand for precise testing instruments in various sectors, including textiles, packaging, and pharmaceuticals. This surge emphasizes the need for manufacturers to adopt rigorous quality assurance measures that leverage advanced testing technologies.

Dr. Emily Foster, a leading expert in materials testing, underscores the critical role of bursting strength testers in ensuring product integrity. She asserts, “A reliable bursting strength tester is essential not only for meeting compliance standards but also for enhancing customer satisfaction through consistent quality.” Her insights reflect the broader industry consensus that robust testing methodologies are integral to maintaining competitive advantage. By implementing state-of-the-art bursting strength testers, companies can better assess their materials' performance, ultimately leading to improved product reliability and a reduction in costly returns or failures.

As we explore the top ten reasons why bursting strength testers are pivotal in quality control processes, it becomes evident that these instruments are more than just tools; they are the backbone of quality assurance strategies that safeguard brand reputation and customer trust.

Significance of Bursting Strength in Quality Assessment of Materials

Bursting strength is a critical parameter in the quality assessment of materials, particularly in industries where the integrity of packaging and product safety is paramount. This property refers to the maximum pressure a material can withstand before rupturing, making it essential for evaluating the durability of products such as corrugated boxes, paper, and textiles. By measuring bursting strength, manufacturers can ensure that their materials meet industry standards and customer expectations, thereby reducing the risk of failures during storage and transportation.

Moreover, consistency in bursting strength testing enables manufacturers to maintain a competitive edge in the market. Using a reliable bursting strength tester equips them to identify variations in material quality and make necessary adjustments in real-time. This not only enhances product reliability but also fosters customer trust. In sectors like food, pharmaceuticals, and electronics, where material failure can lead to safety hazards, the significance of bursting strength becomes even more pronounced, underscoring its vital role in comprehensive quality control processes.

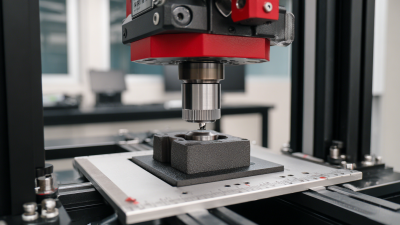

Key Features of Advanced Bursting Strength Testers for Accurate Results

Bursting strength testers play a critical role in quality control processes, particularly in industries where material durability and performance are paramount. Advanced bursting strength testers are equipped with key features that enhance their efficiency and accuracy. One notable feature is the integration of digital display and data logging capabilities, which allow for precise readings and easy documentation of test results. This technological advancement not only streamlines the assessment process but also ensures that the data collected is reliable and easily accessible for further analysis.

Another significant aspect of advanced bursting strength testers is their adaptability to various materials, such as textiles, paper, and plastics. They often include customizable settings to accommodate different testing standards and conditions. Additionally, many models offer real-time analysis and automated calibration, reducing the margin for human error. This versatility and precision in testing contribute to consistent quality assurance, enabling manufacturers to maintain high standards and meet regulatory compliance efficiently. With these innovative features, bursting strength testers are invaluable in safeguarding product integrity and performance in competitive markets.

Understanding the Importance of Bursting Strength Tester in Quality Control Processes - Key Features of Advanced Bursting Strength Testers for Accurate Results

| Feature | Description | Importance in Quality Control | Typical Applications |

|---|---|---|---|

| Digital Display | Provides real-time results for easier monitoring. | Enhances accuracy and reduces human error. | Textiles, Paper, and Packaging |

| Automatic Calibration | Automatic adjustment to maintain measurement integrity. | Ensures consistent results over time. | Manufacturing and Quality Control Labs |

| Data Logging Capability | Records test results for future analysis. | Facilitates quality audits and trend analysis. | Research and Development |

| User-Friendly Interface | Intuitive controls for easy operation. | Reduces training time for new users. | All Industries requiring burst strength testing |

| Customizable Test Settings | Allows adjustment of test parameters per material. | Improves test accuracy and relevance. | Specialized Material Testing |

Industry Applications: How Bursting Strength Testing Enhances Product Reliability

Bursting strength testing is crucial across various industries, particularly in packaging, textiles, and paper manufacturing. This test assesses the ability of materials to withstand pressure without rupture, ensuring that products can endure the rigors of handling, transportation, and usage. For instance, in the packaging industry, reliable bursting strength is essential for materials like cardboard and plastic films. By using bursting strength testers, manufacturers can guarantee that their packaging solutions protect contents effectively, thereby reducing waste and improving customer satisfaction.

In the textile sector, the durability of fabrics is paramount. Bursting strength tests provide insight into how well textiles can resist stress during wear and washing. This is especially important for manufacturers of outdoor and performance clothing, where material integrity can directly impact product functionality and safety. Through rigorous testing, companies can design high-quality textiles that meet consumer expectations and regulatory standards, thereby enhancing their brand reputation and market competitiveness. Ultimately, incorporating bursting strength testing into quality control processes not only fosters product reliability but also drives innovation and efficiency in manufacturing practices.

Interpreting Bursting Strength Results: Best Practices for Quality Control Teams

When it comes to quality control processes in packaging and materials industries, understanding bursting strength results is crucial for ensuring product integrity. The bursting strength tester measures the pressure at which a material ruptures, providing valuable insights into its durability and performance under stress. Quality control teams must effectively interpret these results to make informed decisions about production processes and material selection.

Here are some tips for interpreting bursting strength results: First, always compare the testing results against the manufacturer's specifications or industry standards. This comparison helps identify whether the material meets the required performance criteria. Second, consider environmental factors that may affect bursting strength, such as moisture content and temperature. These variables can significantly skew results, so it’s important to ensure that testing conditions are controlled and consistent.

Finally, make use of historical data by analyzing trends over time. By keeping records of bursting strength tests, quality control teams can identify potential weaknesses in materials or processes, allowing them to take proactive measures before issues arise. This not only improves product quality but also enhances customer satisfaction and brand reputation.

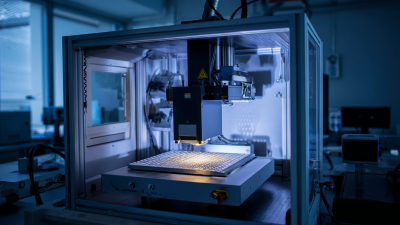

Future Trends in Bursting Strength Testing Technology and Quality Standards

The future of bursting strength testing technology is poised for significant advancements, particularly as industries increasingly prioritize quality control. The rising demand for durable materials across various sectors—aerospace, automotive, and consumer electronics—drives innovation in testing methodologies. Bursting Strength Testers are becoming more sophisticated, incorporating automation and sophisticated software to enhance accuracy and efficiency. This evolution not only improves product quality but also aligns with emerging international standards, ensuring compliance and fostering trust among consumers.

As the market for bursting strength testing equipment expands, it's essential to recognize different testing capacities, categorized into below 5 kN, 5 kN - 50 kN, and above 50 kN. These categories cater to the diverse needs of industries. For instance, aerospace components often demand rigorous testing at higher thresholds to withstand extreme conditions, while consumer electronics may find adequate results in lower ranges.

Tips: When selecting a bursting strength tester, consider the specific requirements of your application. Ensure that the device supports the necessary capacity and complies with relevant quality standards. Regular calibration of testing equipment is crucial to maintain accuracy over time, so always check the calibration records before conducting tests. Additionally, investing in user training can significantly enhance the testing process, ensuring that staff are proficient in operating advanced technology for optimal results.

Related Posts

-

Ultimate Guide to Understanding Thermal Chambers: Selection, Usage, and Best Practices

-

Why Investing in a Tensile Tester Can Transform Your Quality Control Process

-

Solutions for Tailored Environmental Test Chamber Applications

-

Essential Guide to Understanding Universal Tensile Testing Machines for Accurate Material Analysis

-

How to Choose the Right Thermal Test Chamber for Your Product Development Needs

-

How to Choose the Right Temperature Humidity Chamber for Your Specific Testing Needs

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.