Unlocking the Secrets: How a Gloss Meter for Paint Transforms Surface Finishing

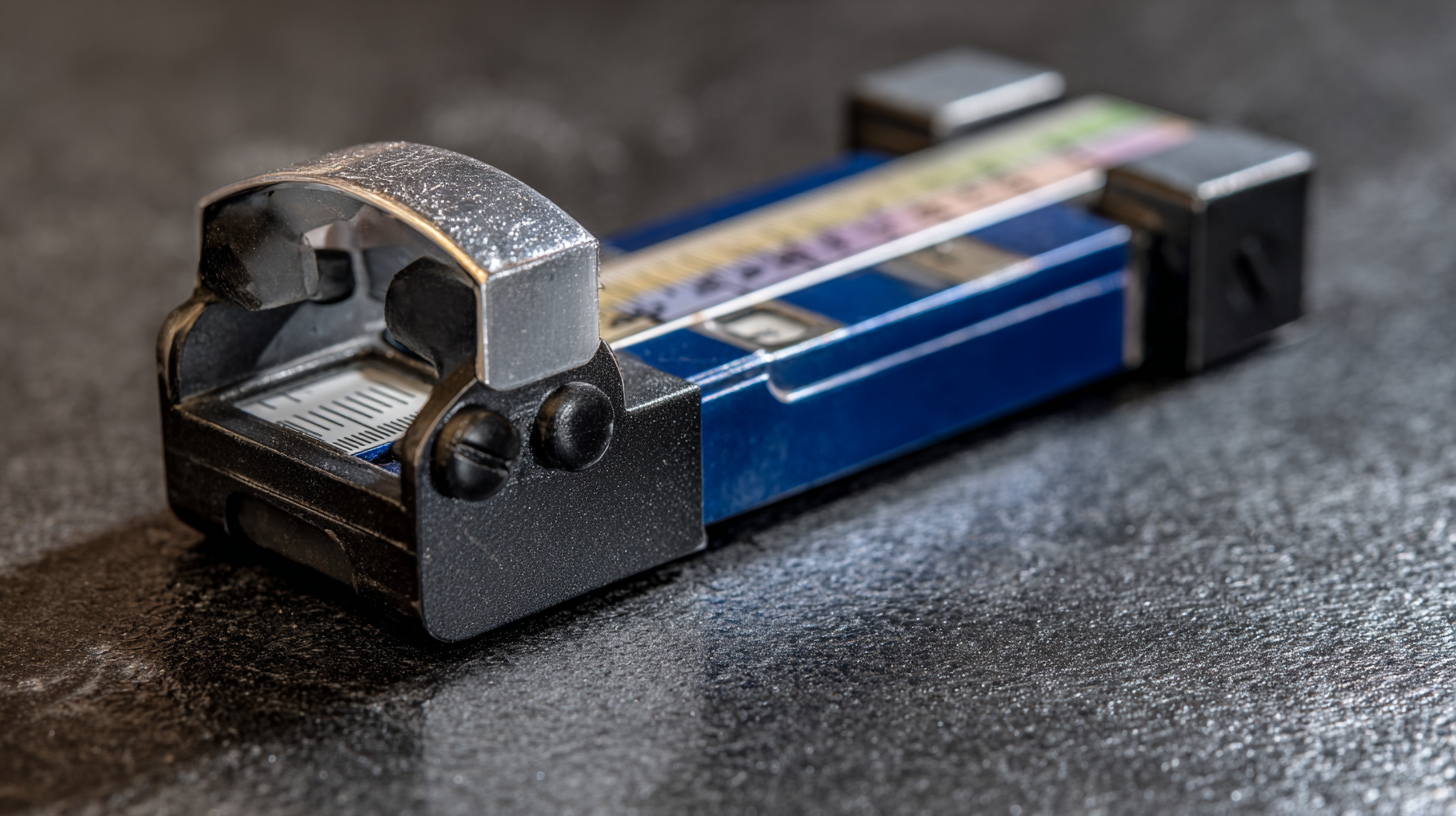

In the world of surface finishing, achieving the perfect sheen can often feel like an elusive goal. That’s where a gloss meter for paint comes into play, unlocking the secrets to achieving the ideal surface quality. This essential tool measures the reflectivity of painted surfaces, allowing professionals to gauge gloss levels with precision and accuracy. By understanding the nuances of gloss measurement, painters and finishers can not only enhance the aesthetic appeal of their work but also ensure consistency across different projects.

In this article, we’ll explore effective tips and techniques for utilizing a gloss meter for paint, revealing how this seemingly simple device can dramatically transform your surface finishing process. Prepare to dive into the world of gloss measurement and discover the hidden potential it holds for elevating your craftsmanship.

Understanding the Basics of Gloss Meters in Paint Finishing

Gloss meters play a crucial role in the paint finishing process by measuring the sheen of surfaces. Understanding the basics of these devices begins with recognizing their function: they quantify the amount of light reflected off a painted surface, providing essential data that can be used to assess quality and consistency. This measurement helps manufacturers ensure that the finished products meet specific aesthetic and functional standards, as different finishes require different levels of gloss.

Moreover, the use of gloss meters allows for precise adjustments in the painting process. By analyzing gloss levels, painters can tweak their techniques or formulations to achieve the desired finish. This capability not only enhances the overall appearance but also contributes to the durability and longevity of the paint. With various types of gloss meters available, from handheld models to sophisticated automated systems, the ability to accurately gauge gloss levels has transformed surface finishing into a more efficient and reliable practice.

The Importance of Surface Gloss in Coating Applications

In the realm of coating applications, surface gloss plays a pivotal role in defining not only the aesthetic appeal but also the performance of the finish. Gloss refers to the sheen or luster exhibited by a surface, influencing how light interacts with it. A high gloss level can enhance color vibrancy and provide a smooth, reflective finish that is often desired in high-end automotive or architectural coatings. Conversely, a matte finish might be preferred for applications where a subtle, understated look is required. Understanding and controlling surface gloss is essential for achieving the desired effect and functionality of the coating.

A gloss meter serves as an indispensable tool for ensuring consistent surface quality in coating applications. By precisely measuring the gloss levels of painted surfaces, manufacturers can maintain strict quality control standards. This instrument allows for adjustments in the coating process to achieve the desired gloss level, thereby transforming the overall appearance and durability of the coating. The ability to measure and analyze gloss not only elevates the quality of finished products but also enhances customer satisfaction, as clients receive surfaces that meet their high expectations for both Look and performance.

Unlocking the Secrets: How a Gloss Meter for Paint Transforms Surface Finishing - The Importance of Surface Gloss in Coating Applications

| Measurement Type | Gloss Level (GU) | Surface Texture | Application Area | Recommended Gloss Meter |

|---|---|---|---|---|

| Matte | 0-10 | Rough | Automotive | Gloss Meter A |

| Eggshell | 10-30 | Slightly Textured | Interior Walls | Gloss Meter B |

| Satin | 30-70 | Smooth | Furniture Finishing | Gloss Meter C |

| Glossy | 70-100 | Very Smooth | Automotive and Industrial Coatings | Gloss Meter D |

| High Gloss | Above 100 | Mirror Finish | Premium Automotive | Gloss Meter E |

Choosing the Right Gloss Meter: Key Features to Consider

When selecting a gloss meter for paint, understanding the essential features is crucial for achieving optimal surface finishing. First, look for a meter that offers multiple gloss measurement angles, such as 20°, 60°, and 85°. Different angles provide varying insights into the surface texture, enabling professionals to assess both matte and high-gloss finishes accurately. According to the Coatings World Market Report, the demand for sophisticated gloss measurement tools has surged by 25% over the past four years, underscoring their importance in today’s coatings industry.

Another critical feature to consider is the device's calibration capabilities. A gloss meter that allows for quick and easy calibration against known standards ensures accuracy and reliability in measurements. Additionally, portability and ease of use are essential, particularly for field applications. Research by the National Association of Manufacturers indicates that 70% of professionals prefer portable devices that deliver quick results without compromising precision.

Tip: Always check for ISO or ASTM certification when choosing a gloss meter. This ensures that the device meets industry standards for measuring gloss, providing peace of mind about the reliability of your readings. Furthermore, investing in a gloss meter with data logging capabilities can enhance quality control processes, allowing for comprehensive tracking of surface finish consistency over time.

Interpreting Gloss Measurements for Optimal Finishing Quality

Gloss meters play a crucial role in the quality control of surface finishing, particularly in the paint industry. By effectively measuring the gloss level of painted surfaces, manufacturers can ensure consistency and adherence to aesthetic standards. According to a report by the ASTM International, variations in gloss finish can influence customer perception and product quality significantly, with studies indicating that a visual gloss difference of just five GU (gloss units) can be detectable by the human eye. This makes precise gloss measurement essential in optimizing finishing quality.

Interpreting gloss measurements requires a thorough understanding of how different gloss levels affect surface performance. High gloss finishes tend to exhibit better resistance to stains and easier cleaning, making them preferable in certain applications. Conversely, satin and matte finishes can mask imperfections and reduce glare but may require more careful handling during the finishing process. The American Coatings Association highlights that approximately 35% of consumer choices are influenced by surface sheen qualities, underscoring the need for manufacturers to invest in reliable gloss measurement tools to achieve desired results efficiently.

Implementing Gloss Meter Results for Improved Painting Techniques

A gloss meter is an essential tool that revolutionizes surface finishing by providing precise measurements of gloss levels in paint. By implementing gloss meter results, painters can significantly enhance their techniques, ensuring that each coat dries to the desired sheen and quality. This data-driven approach allows for adjustments during the painting process, leading to more consistent outcomes and a professional finish.

To maximize the benefits of a gloss meter, it’s important to keep a few key tips in mind. First, always calibrate the gloss meter before use to ensure accuracy. Regular calibration can prevent inconsistencies that might arise from environmental changes or wear and tear on the device. Additionally, taking readings under controlled lighting conditions can further enhance the reliability of the results, allowing for better comparisons and adjustments.

Another tip is to analyze the gloss levels at different stages of the painting process. This includes measuring the gloss after the first coat, touch-ups, and the final layer. By understanding how each layer affects the gloss, painters can make more informed decisions about paint types and application methods, ultimately leading to superior surface finishes.

Related Posts

-

Essential Guide to Understanding Universal Tensile Testing Machines for Accurate Material Analysis

-

Choosing the Right Temperature Humidity Chamber: A Comprehensive Comparison Guide

-

Solutions for Tailored Environmental Test Chamber Applications

-

How to Choose the Right Color Spectrophotometer for Your Needs

-

How to Choose the Right Thermal Test Chamber for Your Product Development Needs

-

Why Investing in a Tensile Tester Can Transform Your Quality Control Process

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.