How to Choose the Right Thermal Test Chamber for Your Product Development Needs

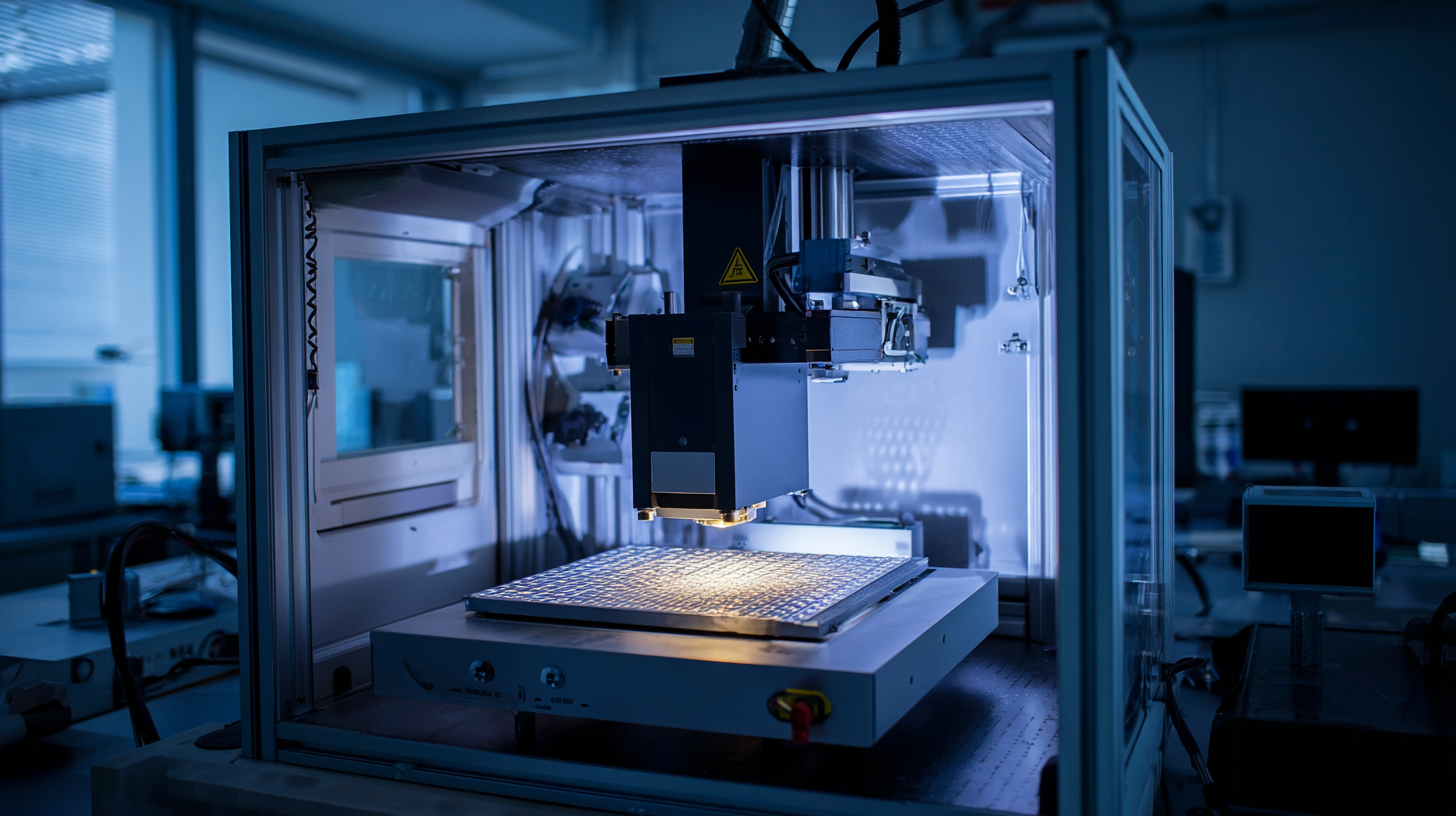

In the realm of product development, ensuring that your products can withstand extreme conditions is essential for their success in the market. A critical piece of equipment in this process is the thermal test chamber, which simulates various temperature and humidity environments to evaluate the performance and reliability of your products. However, with a wide range of thermal test chambers available, selecting the right one can be a daunting task.

Factors such as the size of your product, the temperature range you need, and the specific tests required all play significant roles in making the best choice. This guide will provide you with valuable insights and criteria to consider, helping you navigate the complexities of selecting the ideal thermal test chamber that aligns with your product development needs and ensures that your innovations thrive under any conditions.

Understanding Your Product's Thermal Requirements

Understanding your product's thermal requirements is critical when selecting the right thermal test chamber. Products exposed to extreme temperatures can experience various failures if not properly tested. According to a report by Frost & Sullivan, 70% of product failures can be traced back to inadequate thermal testing during the development phase. The first step in understanding these requirements is to identify the operational temperature range your product must endure, including maximum and minimum temperature limits, as well as the rate of change between these temperatures.

In addition to temperature extremes, it's essential to consider humidity levels and their effects on your product. Many electronics, for instance, are sensitive to humidity, which can lead to corrosion or malfunction. A recent study by the International Electrotechnical Commission revealed that up to 30% of electronic device failures occur due to humidity-related issues. Therefore, it's crucial to choose a thermal test chamber that accommodates not only temperature variations but also varying humidity levels. By aligning your product's specific thermal and humidity requirements with the capabilities of the thermal test chamber, you can ensure more accurate testing and reliable product performance.

Key Features to Look for in a Thermal Test Chamber

When selecting a thermal test chamber for product development, it's essential to consider key features that align with your specific requirements. One of the primary factors is temperature range; high-quality chambers typically offer a range from -70°C to +200°C. According to a recent report by Frost & Sullivan, 68% of product failures in the electronics sector can be attributed to thermal stress, emphasizing the importance of an accurate and versatile temperature range in testing environments.

Another significant feature to examine is the uniformity of temperature distribution within the chamber. A well-engineered thermal test chamber should maintain temperature variations within ±2°C across the entire working space to ensure reliable and consistent test results. The International Electrotechnical Commission (IEC) suggests that testing conditions closely replicate actual operational environments, underlining the necessity for chambers that provide precise humidity control and rapid temperature change rates. These specifications are crucial in fields such as aerospace and automotive, where even minor temperature deviations can lead to critical failures.

Evaluating Size and Capacity for Your Testing Needs

When selecting a thermal test chamber for product development, evaluating size and capacity is crucial. The size of the chamber should correspond to the dimensions of the products being tested. If your items are larger, it’s essential to choose a chamber that can accommodate their bulk without compromising the testing conditions. Additionally, the internal configuration should allow for proper airflow and uniform temperature distribution around the product, ensuring accurate test results.

Capacity is another key factor to consider. This encompasses not only the volume of the chamber but also its temperature range and the rate of change. Depending on your testing requirements, you may need a chamber with a wide temperature range to simulate various environmental conditions. Furthermore, consider whether your testing will involve multiple samples simultaneously, as this will dictate the overall capacity needed for effective testing without overcrowding the chamber, which could affect thermal performance and outcomes.

How to Choose the Right Thermal Test Chamber for Your Product Development Needs

| Test Chamber Size | Internal Volume (cubic feet) | Temperature Range (°C) | Cooling Capacity (kW) | Heating Capacity (kW) | Control Type |

|---|---|---|---|---|---|

| Small | 1.5 | -20 to 100 | 2.0 | 3.0 | Digital |

| Medium | 5.0 | -40 to 150 | 5.0 | 7.0 | Programmable |

| Large | 10.0 | -70 to 300 | 10.0 | 15.0 | Touchscreen |

Assessing Budget vs. Long-term Investment in Thermal Equipment

When selecting a

thermal test chamber

for product development, it's crucial to carefully assess the balance between

budget constraints

and the long-term investment potential of the thermal equipment. While it may be tempting to opt for a less expensive model to save immediate costs, this short-sighted approach can lead to higher expenses down the line. Cheaper chambers may lack the necessary features or reliability, resulting in inaccurate testing and potentially costly product failures.

On the other hand, investing in a

high-quality thermal test chamber

often pays off in the long run. These advanced models typically offer

better precision,

a wider temperature range, and more robust data collection capabilities. Furthermore, they can accommodate future product testing needs, reducing the likelihood of needing to purchase additional equipment as your development processes evolve. By viewing the acquisition of thermal testing equipment as a

strategic investment

rather than just a budgetary expense, companies can significantly enhance their

R&D efficiency

and ensure

safer, more reliable products.

Choosing Between Custom vs. Standard Test Chamber Solutions

When selecting a thermal test chamber for product development, one key consideration is whether to opt for a custom or standard solution. Standard test chambers offer the advantage of being readily available and cost-effective, making them suitable for companies with straightforward testing requirements. These models typically come with set temperature and humidity ranges, providing reliability for general applications. However, for products that demand specific testing parameters or conditions, a standard solution may not suffice.

On the other hand, custom thermal test chambers are designed to meet unique specifications tailored precisely to a product's development needs. This approach allows for greater flexibility in terms of temperature profiles, size, and additional features like specialized monitoring systems. However, it typically involves longer lead times and higher costs. Companies should evaluate their testing requirements carefully—if standard chambers do not align with a product's criteria, investing in a custom solution could lead to more accurate and relevant testing results, ultimately supporting better product performance and compliance in the market.

Related Posts

-

Essential Checklist for Selecting the Right Temperature Test Chamber for Your Testing Needs

-

Solutions for Tailored Environmental Test Chamber Applications

-

Choosing the Right Temperature Humidity Chamber: A Comprehensive Comparison Guide

-

How to Choose the Right Color Spectrophotometer for Your Needs

-

7 Compelling Reasons to Invest in Thermal Chambers for Your Business Success

-

Essential Guide to Understanding Universal Tensile Testing Machines for Accurate Material Analysis

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.